FEATURED PRODUCTS

-

Hartness 835 Stainless Steel Drop Packer0 out of 5

Hartness 835 Stainless Steel Drop Packer0 out of 5 -

Belcor 250/505 Combo0 out of 5

Belcor 250/505 Combo0 out of 5 -

ADCO 15D105 Cartoner0 out of 5

ADCO 15D105 Cartoner0 out of 5

BEST SELLING PRODUCTS

-

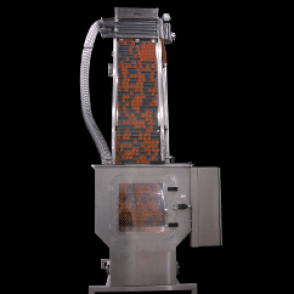

Simplimatic Cap Sorter Unscrambler Feeder0 out of 5

Simplimatic Cap Sorter Unscrambler Feeder0 out of 5 -

-

Arrowhead Arrowselect® Table Top Conveyors0 out of 5

Arrowhead Arrowselect® Table Top Conveyors0 out of 5

LATEST PRODUCTS

-

Wexxar WFT 300 out of 5

Wexxar WFT 300 out of 5 -

-

Viking Masek FFS0 out of 5

Viking Masek FFS0 out of 5