FEATURED PRODUCTS

-

Hartness 835 Stainless Steel Drop Packer0 out of 5

Hartness 835 Stainless Steel Drop Packer0 out of 5 -

Belcor 250/505 Combo0 out of 5

Belcor 250/505 Combo0 out of 5 -

ADCO 15D105 Cartoner0 out of 5

ADCO 15D105 Cartoner0 out of 5

BEST SELLING PRODUCTS

-

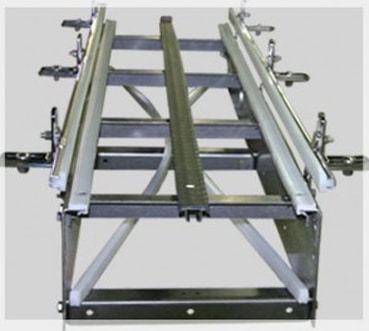

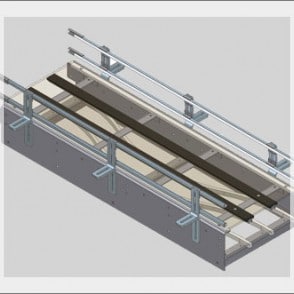

Arrowhead Mat Top Conveyors0 out of 5

Arrowhead Mat Top Conveyors0 out of 5 -

GC Evans Bottle & Can Warmers0 out of 5

GC Evans Bottle & Can Warmers0 out of 5 -

Tetra Pak High Shear Almix System0 out of 5

Tetra Pak High Shear Almix System0 out of 5

LATEST PRODUCTS

-

6500 Gallon Stainless Tanks0 out of 5

6500 Gallon Stainless Tanks0 out of 5 -

Flexicon Super Sack Unloading System0 out of 5

Flexicon Super Sack Unloading System0 out of 5 -